Concrete Slabs in Grand Prairie, TX

Engineered Structural Slab Solutions

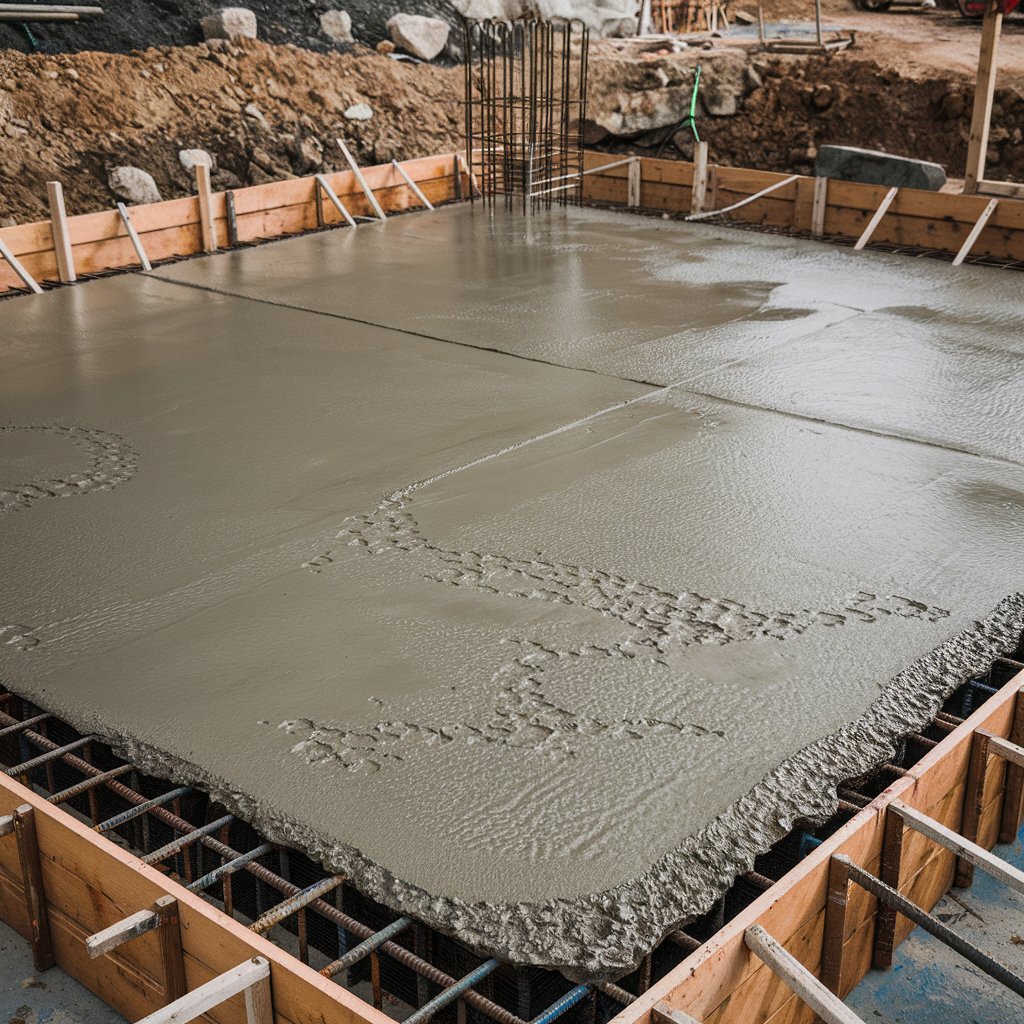

Grand Prairie Concrete Pros creates well-structured concrete slabs with precision for all aspects of your construction projects. This includes developing homes, garages, and backyards. The quality of your concrete slab will ultimately depend on the stability of your structure; therefore, our slabs are built using the highest standards of strength (with structural integrity), so they last for decades without shifting or cracking.

The first step of our process involves evaluating the entire area where the project will be completed and preparing the ground (soil) to ensure it will hold the weight of the slab for years to come. As part of this evaluation, we include the installation of heavy reinforcement into each slab (such as rebar or wire mesh), as well as utilizing special high-strength concrete mixes to meet the individual load requirements of the building. With a focus on completing each slab perfectly finished and properly cured, we offer the most professional product available for the ideal base for residential additions, utility buildings, and industrial equipment pads.

Get A Free Quote

What is a Concrete Slab?

A concrete slab is a horizontal, level surface created by pouring concrete. Slabs are useful due to their ability to support a variety of structures and can be found in both indoor and outdoor settings. The slab is a base used to build many different types of projects, including buildings, patios, etc. The slab is also important to provide a solid base for structures, which will help ensure long-term durability and structural stability. A well-made concrete slab is critical to the success and longevity of your project in Grand Prairie’s weather conditions. For example, a utility pad or base for a structure such as a home, office building, etc., when properly laid, will help distribute the weight evenly over the dirt below.

We construct slabs with a focus on providing sufficient thickness and internal reinforcement so they work as a single unit. This provides the structural integrity required to keep the surface from buckling under heavy loads and/or shifting due to the moisture content that fluctuates with the seasons in the ground conditions of North Texas.

Our Concrete Slab Services

Our comprehensive suite of slab services provides the structural integrity required for any scale of construction. We utilize specialized pouring techniques and reinforcement strategies to ensure that every surface we create is perfectly leveled and capable of supporting its intended load-bearing requirements.

Residential Concrete Slabs

- Concrete Slabs for Home Foundations: We produce high-quality residential footings and slabs that will be the foundation of your new home. We also have a strong focus on ensuring the slabs are properly leveled and contain adequate moisture barriers to keep your home safe and secure.

- Garage Floors: Garage slabs are designed to withstand the weight of cars and equipment. Our mix designs for garage floors produce extremely high-strength slabs that will not crack under normal use. Additionally, our garage floor finishing techniques leave a smooth surface that makes it simple to maintain.

- Slab Bases for Sheds and Storage Units: As part of providing a solid foundation for your shed or storage unit, we make sure that the slab does not sink into the soil. This helps you to avoid problems with your door and prevents damage to your stored goods from water.

- Concrete Patio Foundations: The ultimate base for any patio or outdoor kitchen is a well-designed and constructed concrete slab. We pour extremely thick slabs (up to 6 inches) that include rebar for added strength and stability.

- Heavy-Duty Driveway Substrates: While many people think that a good driveway is only about how attractive it looks, the most important factor in a driveway’s longevity is the quality of the base material it sits upon. We lay down heavy-duty subgrade materials that are compacted to ensure your driveway can support heavy traffic and won’t buckle over time.

Commercial Concrete Slabs

- Warehouse Floor Slabs: We provide a wide variety of large-scale pours for warehouse applications that demand maximum durability. Our large-scale pour slabs are extremely flat and hard-wearing, so they can support heavy forklift traffic and high-rack storage.

- Commercial Retail Space Foundations: Whether you’re finishing your retail space with carpet, tile, hardwood, or something else entirely, our commercial-grade slabs provide a smooth base for you to build upon. We guarantee that the slab is perfectly level and has been fully cured so you can meet the exacting standards of today’s modern retail store construction.

- Commercial Office Building Bases: We supply structural slabs for professional business parks where long-term stability is essential. We design each of our commercial slabs to meet all applicable local building codes and support all necessary plumbing and electrical systems for an office environment.

- Parking Lot Substrate Pours: Behind every successful, durable asphalt or concrete parking lot is a carefully laid out substrate. We take the extra steps necessary to ensure the correct grading and sufficient rebar in each parking lot substrate so that potholes and other drainage-related issues never develop in a high-traffic commercial zone.

- High-Strength Industrial Facility Floor Slabs: For businesses with heavy equipment, chemical exposure, or orhigh-impactt loading, we can provide custom-made slabs with higher PSI ratings than standard slabs. We design these industrial-grade floors to withstand high impacts and vibrations while maintaining their overall structural integrity.

Customized Concrete Slabs

- Light Structure Floating Slabs: Light structure floating slabs are used when a separate footing isn’t needed for the structure. They act as a single unit with the surrounding soil as the structure moves. They are a cost-efficient way to complete small, unheated projects such as detached garages or sheds in the Grand Prairie area.

- Post-Tensioned Slabs for Challenging Soil Conditions: Post-tensioning is a technique we utilize in the North Texas region, specifically in areas with expansive clay soils. We use this method to compress the concrete using steel cables, which greatly increases the resistance of the slab to the cracking that occurs due to soil movement.

- Insulated Concrete Slabs for Energy Efficiency: Insulation can be added to the underside of our insulated concrete slabs to help control interior temperatures. This is a fantastic option for those who want to lower the amount of money spent on heating and cooling their homes or workspaces.

- Elevated Concrete Slabs for Improved Drainage: When there is a concern for water runoff in a particular area, we can design elevated slabs to keep your property free of standing water and direct water flow around the building perimeter.

Why Choose Grand Prairie Concrete Pros for Your Concrete Slab?

Choosing the right partner for your foundation work is essential for the long-term health of your structure. We combine local geological knowledge with rigorous construction standards to ensure that every slab we pour provides a lifetime of reliable service.

- Regional Expertise: Our local knowledge allows us to build your slab with the Texas region’s soils and climate in mind. In addition to our knowledge of the region, our crew understands how the clay in North Texas behaves under various moisture levels and designs each slab to be resistant to both heaving and shifting due to the region’s moisture levels.

- Precision Leveling: We are committed to creating an accurate slab. Utilizing professional-grade laser technology as well as screeding equipment, we create perfectly level surfaces that will satisfy all architectural specifications. This is important when installing walls or flooring because it ensures that everything is properly aligned.

- High-Durability Mixes: The only high-grade concrete mixes we utilize are those that can handle the extreme temperatures and rapidly changing weather typical of the DFW metroplex. We also utilize high PSI (pounds per square inch) concrete along with other additives to ensure your slab maintains its structural integrity during the extreme heat of Texas summers.

- Customized Engineering: We believe that no two projects are alike, and therefore, we do not provide “one size fits all” solutions. Instead, we design each slab to meet your project’s specific needs. The thickness, amount of rebar, and finish of your slab will be customized to fit the anticipated load and usage of the space.

- Timely Project Coordination: We respect your project timeline and strive to complete your slab in the most timely manner possible. A slab is typically the first phase of a larger building project, and we are aware of this fact. Therefore, we coordinate our pour and finishing schedules to allow you to stay on track with your overall project.

- Competitive Pricing: We feel that our pricing is fair and competitive for the quality of service and materials that we provide. We will provide you with a detailed estimate that accurately reflects the quality of our materials and labor. Additionally, we provide excellent value to property owners in Grand Prairie with a foundation they can rely upon.

Our Concrete Slab Process

A properly installed concrete slab is the result of technical expertise and a systematic approach. Our process ensures that every slab we pour in Grand Prairie is engineered to handle the specific load-bearing requirements of your project while resisting the local environmental pressures.

- Assessment of Site: A thorough assessment is conducted to determine how best to address your site’s unique needs. Specifically, we will evaluate the condition of your soils in order to determine what additional measures may be needed before construction to help mitigate the potential for settlement or movement due to expansive clays; this is especially important as expansive clays can be found throughout North Texas.

- Customized Design: We develop a design for your slab specifically based on the requirements of your project. This could include designing a slab to support heavy industrial loads or a small residential equipment pad, calculating the correct PSI mix and/or thickness to ensure long-term structural stability.

- Site Preparation: We prepare the site properly to ensure a stable foundation. To do so, we grade the site properly, dig out the base material, and compact a layer of crushed stone or gravel to create a firm sub-base that allows for proper drainage and even support over the entire surface.

- Forming and Reinforcement: We form the slab and install reinforcing steel (rebar) or wire mesh to increase the overall strength of the slab. The steel reinforcing elements are installed into the slab according to established engineering practices and serve as the internal structure, which helps to resist tensile forces and provide crack resistance.

- Pouring Concrete: With the correct mix of materials, we then pour and level the concrete to our specifications. Our crew takes great care to control the flow of the concrete and place it evenly, using specialized screeding tools to create an ideal, smooth, flat, and consistent surface from edge to edge.

- Finishing: We provide a finish to your slab to suit the needs of your application. For example, a rough broom finish would be suitable for an outside utility pad, while a glass-smooth trowel finish would be better suited to an inside shop floor, etc.

- Curing: We ensure proper curing conditions for your slab to maximize its strength and longevity. We closely monitor the moisture levels of the slab during the critical initial days post-pour to allow the concrete to reach its full chemical strength and minimize premature surface wear.

Types of Concrete Slab Finishes

The final appearance of your concrete slab is defined by the finishing technique applied during the curing process. Depending on the intended use of the surface—whether it is a functional interior floor or a decorative outdoor area—we offer various finishes to ensure the perfect balance of safety, durability, and style.

- Smooth Trowel: An ideal interior or protected area (e.g., under tile) finish; it is made possible through the application of a steel trowel to create a smooth, extremely hard, dense surface that is very easy to clean. A smooth finish on garage floors, warehouse interiors, or any slab that will receive tile or wood flooring is the most common application for this type of finish.

- Broom Finish: Offers an exterior non-slip surface; by pulling a special industrial broom over the wet concrete, we create several small ridges which provide good traction. The broom finish is the most popular and practical finish for the base of driveways, utility pads, and walkways, because it provides safety from slipping in wet weather.

- Exposed Aggregate: Offers a decorative textured finish. Through removing the top layer of the concrete paste, we expose the aggregate (stone and gravel) within the mixture. As such, the result is a rugged surface that offers excellent slip resistance and can be used for heavy-duty outdoor applications and high-traffic areas.

- Stamped: Allows for various patterns and textures to be added to achieve a decorative finish. Stamping can be applied to the same slabs that will also act as a finished floor, allowing for replication of the look of expensive materials such as slate or brick. Stamped finishes may be used for patio foundations that you wish to make a design element of your home.

Concrete Slab Maintenance Tips

To maximize the lifespan of your investment, following a routine preservation schedule is essential. While a professionally poured slab is designed for extreme durability, taking proactive steps helps maintain the surface’s structural integrity and keeps it looking clean and professional for decades.

- Re-seal Every 2-3 Years: A good quality penetrative sealer will create an imperceptible shield around your concrete to stop oils and chemicals from penetrating the concrete pores. This is most important when you have a garage or warehouse floor where there may be automotive fluid spills.

- Clean Spills Quickly: While concrete is very durable, it is naturally porous. Wipe up any spills (oil, grease, acidic) as soon as possible so that these spills don’t have a chance to soak through the surface and stain your slab.

- Avoid De-icers in Winter: The salt used in some de-icer products triggers a chemical reaction, causing the top layer of the concrete to break away (spall). When we get the occasional freeze here in North Texas, we recommend using sand for traction to protect the finish of your slab from being damaged by the chemicals.

- Repair Small Cracks Promptly: Even if you notice a hairline crack caused by normal ground settling, fill this crack with a professional-grade sealant as quickly as possible. If water gets past the sealant, it will reach the subbase and cause soil erosion, potentially creating larger structural problems down the road.

Ready to Start Your Concrete Slab Project?

Whether you’re laying the foundation for a new home or creating a sturdy base for your backyard shed, Grand Prairie Concrete Pros is here to ensure your project starts on solid ground. Contact us today for a free consultation and quote. Let’s build a foundation that will stand the test of time.

Call us: (682) 222-9008

Email: service@grandprairieconcretepros.com

Grand Prairie Concrete Pros: Pouring quality into every slab in Grand Prairie,

Frequently Asked Questions

- Initial set: 24-48 hours

- Ready for foot traffic: 3-4 days

- Ready for vehicle traffic: 7-10 days

- Full strength: 28 days